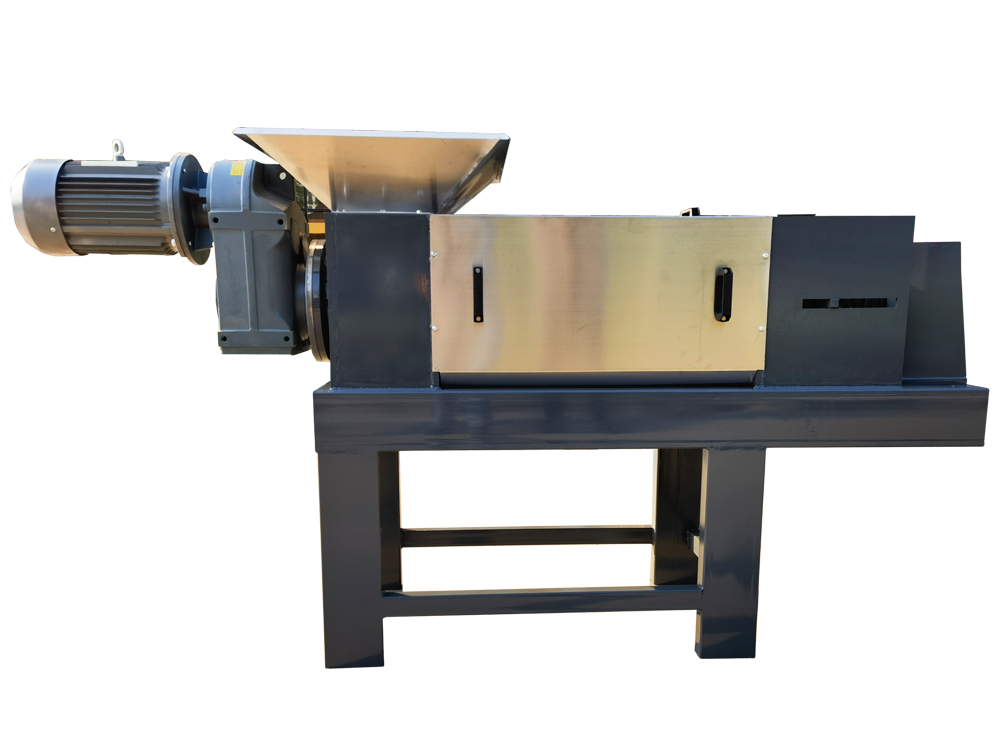

Dewatering screw presses are machines designed for the efficient separation of liquids and solids from various types of sludge or wastewater. These versatile devices play a crucial role in the field of solid-liquid separation, offering an effective solution for industries such as wastewater treatment, food processing, and pulp and paper production.

The dewatering process is accomplished through the use of a screw press mechanism, which applies mechanical pressure to the sludge or slurry. The screw press typically consists of a helical screw, a set of screens or perforated plates, and a housing. The sludge is introduced into the system, and as the screw rotates, it conveys the material along the length of the press.

As the sludge moves through the press, the helical screw compresses and dewaters the material. The liquid phase is forced through the openings in the screens or plates, leaving behind a drier and more concentrated solid cake. The separated liquid, often referred to as filtrate or effluent, can be further treated or disposed of, while the dewatered solids are suitable for disposal or beneficial reuse.

One key advantage of dewatering screw presses is their ability to handle a wide range of sludge types with varying levels of moisture content. This adaptability makes them suitable for applications with different sludge characteristics, ensuring optimal performance across diverse industries.

Industries that generate significant amounts of sludge, such as wastewater treatment plants, can benefit from the cost-effective and environmentally friendly nature of dewatering screw presses. The reduced moisture content in the resulting cake leads to lower transportation and disposal costs, as well as potential opportunities for resource recovery.

In conclusion, dewatering screw presses are integral to modern wastewater treatment and other industries that deal with sludge or slurry. Their efficient and reliable solid-liquid separation capabilities contribute to the sustainable management of waste materials while offering economic and environmental advantages to various sectors.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China